INCOMPARABLE EXPERTISE

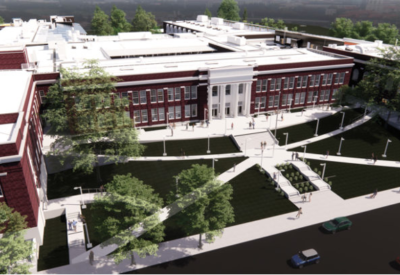

Celebrating Portland Public Schools Bond Projects!

Portland residents voted to pass several bonds that have added modern accommodations to its major educational facilities, while keeping their historic features. Stagecraft, a Portland based company since 1960, is proud to be a part of these monumental projects.

ETCP Certified

Stagecraft is an ETCP Recognized Employer, committed to reduce risk and promote workplace safety.

Stagecraft agrees to abide by these Best Practices:

- Utilize ETCP Certified Electricians in management/lead/supervisory positions.

- Utilize ETCP Certified Technicians where appropriate.

- Promote electrical safety and safe practices in venues where we work.

- Encourage and support continuing education/training for renewal of ETCP credentials.

- Promote honesty and integrity to ensure electrical systems meet industry standards.

- Support industry initiatives to further electrical safety and research to promote safer venues.